(1) Standard offers excellent maintainability and wear resistance that meet the high demands of the electric and electronics industry, contributing to significant productivity improvements.

Standard Pumps are capable of conveying high-viscosity fluids like positive/negative electrode materials as well as high-concentration slurries, and of supplying coating fluid to coaters at rechargeable lithium-ion battery production sites. In addition, Standard Dispensers contribute to improved cycle time and quality in the application of adhesives and grease to electronic parts

(2) Standard Pumps have been introduced to convey high-viscosity fluids and to apply and fill adhesives in the production of automobiles and various other components.

Standard Pumps are introduced for conveying various fluids such as lubricants, polishing solutions, mold-releasing agents, adhesives, and silicone resins, as well as for supplying fluids to dispensers. Meanwhile, Standard Dispensers contribute to improved work efficiency and cost savings in the application and filling processes for various kinds of sealants, adhesives, grease, and other materials.

(3) Standard products are regularly used in production lines for ink, paint, adhesive tape, and high-performance films

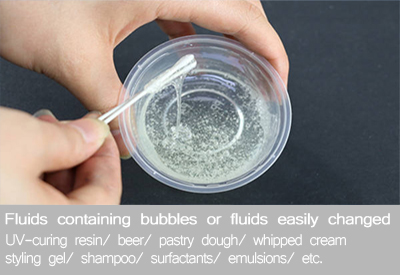

Standard Pumps ensure conveyance without changing the fluid, even with UV resins and emulsions prone to alteration. Metered conveyance is also possible for various other fluids-from low-viscosity fluids such as methanol and caustic soda to high-viscosity fluids such as printing ink and adhesives, as well as fluids containing bubbles

(4) Standard Pumps feature an easy-to-disassemble/wash structure for excellent maintainability, making them a popular choice for the production of cosmetics.

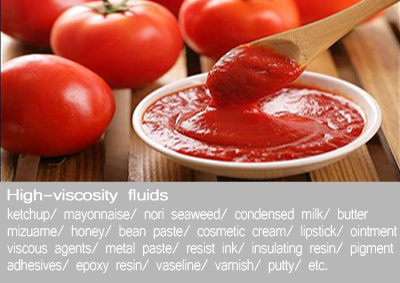

Whether conveying low-viscosity fluids such as lotions and milk lotions, or high-viscosity fluids such as creams or ointment, Standard Pumps provide non-pulsating, metered conveyance. The pumps are also capable of conveying and filling without subjecting materials to changes, whether with shampoos or other fluids that foam when stirred, or with delicate scrubs for facial foams and other applications. Standard Pumps are also easy to disassemble and wash, making them ideal for production lines with frequent fluid changes.

(5) Standard products are used for conveying, drawing, mixing, and filling beverages, brewed food, seasonings, and other prepared dishes.

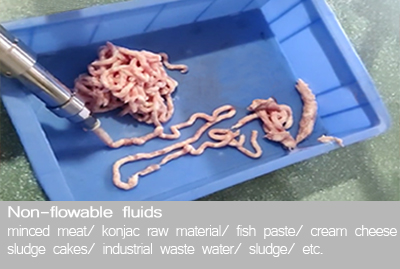

The foods we eat are many and varied, including beverages, confectionery, bread, meat, fish and meat paste, frozen and other ready-made packed food, brewed food, seasonings, dairy products, and various other prepared dishes. Standard Pumps have been adopted by food production sites that handle high-viscosity fluids, non-flowable fluids, fluids with solids, fiber and/or bubbles, and delicate fluids.