dispensing valve PEN7000

Item Number:SK-M-PEN7000

Dimensions:(single valve) L:480mm D:60mm

Weight:3200g

Recommended Fluid Viscosity:0-6000000cps

Delivery revolution(ml): 7ml/rev

Motor max rpm/min:0-120rpm/min

Maximal dosing quantity/min:840ml/min

Material Stator:FFKM FKM EPDM HNBR

Material Screw:SUS304 SUS306 AL

Motor:Brushless DC servo integrated motor

Product Name: #dispensing #dispensing valve #adhesive valve #glue dispensing valve #dosing valve #measuring valve #controlled volume pump #screw valve #dosing head #micro dispensing #adhesive dispenser #micro dispensing pump #liquid dispensing valve #glue dispenser valve #

Description of fluid dispensing valve seriesproduct

Standard SK-M-PEN Series products are suitable for a variety of viscous characteristics of the medium (up to 6,000.000mpas), for you to bring the pulse-free, low shear, high-precision, quantitative linear transmission of the new design concept.

Standard screw dispensing valves, adhesive pumps, filling systems and other products, widely used in the world of consumer electronics, automotive electronics, solar energy, food, daily cosmetics, chemical, steel, paint, 3D printing and other industries.

Technology

The manufacture of Standard micro-dispensing valve is based on the principle of infinite circulation piston, that is, the principle of screw. The screw valve can provide high precision volume conveying and can be reversed to make the material flow back, so there will be no drop on the discharging side. In order to adapt from low viscosity to high viscosity of a variety of media precision delivery, Standard continue to improve and innovate SK-M-PEN dispensing screw valve series.

Advantage

(1) To ensure the perfect uniformity of the starting point, corners and end of the glue line |  |

(2) Output flow constant, steady, no pulsation, no shear | |

(3) Accurate metering, flow error less than 1%, special model less than 0.5% | |

(4) Especially suitable for all kinds of ultra small flow situation, the minimum flow can reach 0.001ml | |

(5) Apply to all kinds of high viscosity, granular media, the highest viscosity can reach 6,000,000cps | |

(6) The output flow is proportional to the rotational speed and is not affected by the change of viscosity, pressure and temperature of the media. | |

(7) A good self-priming and suction function, to avoid the media dripping, drawing, dropping and other phenomena | |

Applicable Medium

(1). A variety of adhesives, silicone, two-component adhesive, packaging, sealant, etc.

(2). All kinds of solder paste, conductive slurry, RTV gum, anaerobic rubber, epoxy resin, polyurethane, etc.

(3). A variety of UV paint,coating, thick paint, solvent paint, additives, suspension agent, viscous raw materials, emulsion, grease and so on

Application Industry

(1). Automotive industry: engine, body, lamp, window, airbag, Cooler, tubing, ABS, ESP, sensors, such as dispensing, potting application

(2). Electronics industry: All kinds of touch screen, Shell package, PCB board, components, connectors, insulators, speakers and other dispensing, potting application

(3). Photovoltaic solar energy: conductive slurry delivery, wafer cutting components of rubber conveyor, junction box bonding, potting, assembly seals, etc.

SK-M-PENsuitable for all kinds of high viscosity, shearing sensitivity, grinding media

(1). Silicone Resin

(2). Metal Slurry

(3). Viscous medium (anaerobic medium)

(4). Coating

(5). High precision Point coating

(6). Can be integrated with robots and axes

SK-M-PEN Series of Standard brands have different Models

SK-M-PEN Series of Standard brands have different Models ( SK-M-PEN100; SK-M-PEN150; SK-M-PEN300; SK-M-PEN450; SK-M-PEN600; SK-M-PEN750; SK-M-PEN1000; SK-M-PEN1500; SK-M-PEN3000; SK-M-PEN7000 )Which can be applied to different usage, it can be integrated into the existing production line, also be used in desktop dispensing.

All the SK series was produced under the principle of screw pump with self-sealing function. The spiral structure makes the material conveying very gentle. The material transported through SK series products will be almost without any shearing force.Even if the high viscosity material SK series products can also make the high viscosity material perfect back suction through the rotor rotation .Cleaning dispensing valve and mixing point rubber valve is very convenient, material replacement can also be completed quickly

SK-M -PEN7000 Product Description

The new volume precision metering valve SK-M -PEN7000 produced by Standard is mainly used in medium transmission from low to high viscosity

Function Principle

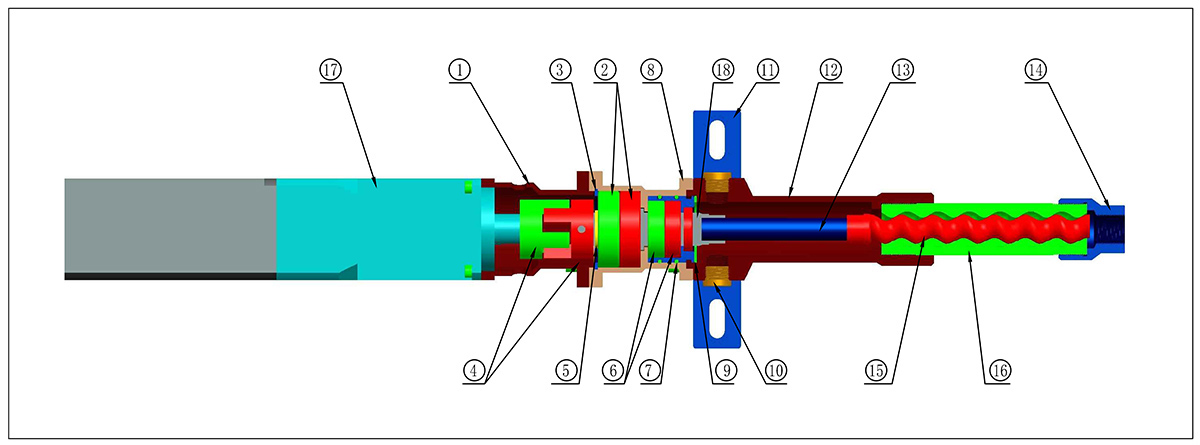

SK-M-PEN series screw valves are designed with screw structure and pressure-proof seal. The rotor and stator are self-sealing and easy to replace. The transmission function is realized by directional rotation of the rotor in the stator cavity. The conveying process does not produce shear effect on the medium, so it does not have any effect on the properties of the medium. At the same time, it can easily realize the suction function of the media through the motor reversal, to ensure the cleanliness of the media and materials, and completely solve the problem of the media dripping and drawing

Application

The best volume precision quantitative transport—widely used in various dispensing, line coating, filling, sealing application occasions.

Scope of Application

(1). Electronics Industry

(2). Semiconductor industry

(3). lcd/led

(4). PV Solar Energy industry

(5). Pharmaceutical Industry

(6). biochemical industry

(7). Laboratory

(8). optics and optoelectronics industry

(9). SMD/SMT

Technical Features

(1). true volumetric conveying

(2). back-suction function

(3). is suitable for all kinds of viscous media

(4).easy to clean

(5). flow is not affected by pressure change

(6). Precision Measurement

(7). no need to install any valve

(8). transmission pressure range 16-20 Bar

TECHNICAL DATA SK-M-PEN7000

| Item Number: | SK-M-PEN7000 |  |

| Dimensions: | (L)480mm; ø 60 mm | |

| Weight: | 3200g | |

| Input Pressure(bar): | ≤6 | |

| Output Connection(bar): | ≥20 | |

| Input Connection: | 1/4“ | |

| Output Connection: | Luer lock with O ring | |

| Recommended Fluid Viscosity min/max(cps): | 0-6000000 cps | |

| Delivery Revolution(ml): | 7ml/rpm | |

| Motor min/max(rpm): | 0~120rpm/min | |

| Maximal dosing quantity/min(ml/min): | 840ml/min | |

| Accuracy Of Dosing: | ≤±1.5% | |

| Material Screw: | SUS304、SUS316、AL | |

| Material Stator: | FKM、FFKM、EPDM、PU、etc | |

| Material Contact Part: | SUS304、SUS316、AL、etc | |

| Motor: | German brushless DC servo integrated motor with drive and reducer |

(1). The maximum working pressure is proportional to the self sealing force and viscosity, which can be calculated by the data provided by the manufacturer.

(2). The transport rate is proportional to the speed of the micro pump.

(3). Volume flow depends on viscosity and primary pressure.

Technical data comparison of SK-M-PEN series pump

| Standard SK-M-PEN series monocomponent dispensing valve technical parameter | |||||||||

| I T E M | SK-M PEN150 | SK-M PEN300 | SK-M PEN450 | SK-M PEN600 | SK-M PEN750 | SK-M PEN1000 | SK-M PEN1500 | SK-M PEN3000 | SK-M PEN7000 |

| Delivery revolution(ml) | 0.003ml | 0.01ml | 0.06ml | 0.2ml | 0.4ml | 1ml | 1.6ml | 3ml | 7ml |

| Smallest dosing quantity | 0.0003ml | 0.001ml | 0.004ml | 0.015ml | 0.03ml | 0.075ml | 0.15ml | 0.25ml | 0.55ml |

| Adjustable dosing flow | 0.0003-0.36ml/min | 0.001-1.2ml/min | 0.004-7.2ml/min | 0.015-24ml/min | 0.03-48ml/min | 0.075-120ml/min | 0.15-192ml/min | 0.25-360ml/min | 0.55-840ml/min |

| Motor rpm/min | 0-120 rpm/min | ||||||||

| Recommended fluid viscosity | 0-6000000cps | ||||||||

| Input Connection | 1/8“ | 1/8“ | 1/8“ | 1/8“ | 1/4“ | 1/4“ | 3/8“ | 3/8“ | 3/8“ |

| Input min Max pressture | 0-6bar | ||||||||

| Output Connection | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring | lucr lock with O ring |

| Output mux pressure | 16-20bar | ||||||||

| Matcrial Rotor | SUS304; SUS316; ALUMINUM | ||||||||

| Matcrial Stator | FKM; NBR; EPDM; HNBR; FFKM | ||||||||

| Matcrial Contact part | SUS304; SUS316; ALUMINUM | ||||||||

| Dimensions | L:210mm Dia:33mm | L:210mm Dia:33mm | L:250mm Dia:33mm | L:270mm Dia:35mm | L:376mm Dia:40mm | L:415mm Dia:40mm | L:440mm Dia:40mm | L:450mm Dia:60mm | L:480mm Dia:60mm |

| Weight | 320g | 350g | 380g | 400g | 1300g | 1500g | 2300g | 2800g | 3200g |

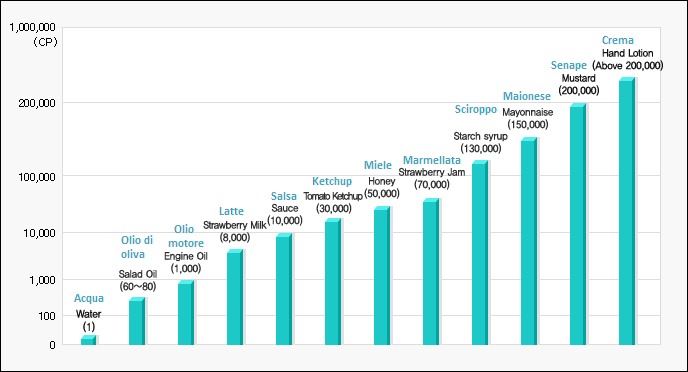

Medium viscosity chart

The endless piston principle?

(1). The functional principle of the Standard dispenser is similar to that of an endless piston dispenser .

(2). The special conveying geometry enables continuous , pulsation – free dispensing flow . Reversing the direction of rotation ( suck – back function ) prevents dripping and leads to a controlled thread break of the material . Standard delivers high – precision and clean dispensing results .

(3). Particularly sensitive material with high viscosity and filers are treated gently due to the low shear stress and low pressures.

What kind of medium can be dosed with the SK-M-PEN series ?

(1). Light cured epoxy resin, toluene, phenol, production agent, heat curing, gasoline, high filling liquid,

(2). Shear sensitive adhesive, LED resin taste, hot conductive paste, solder paste, room temperature vulcanized rubber, silver paste, flux

(3). Industrial oils, perfumes, cosmetics and pharmaceuticals, biological suspensions, silicone, lubricants, alcohol, MEK, thermal grease,

(4). Polyurethane, solder paste, paint and ink, primer, acetone, epoxy, electrolyte solution, isopropyl alcohol and so on.

What can be the reason for too little or no flow of medium ?

(1). Potential cause: Motor (dispenser cable) is not connected

Solution: Connect motor to eco-CONTROL unit Check all connections!

(2). Potential cause: Dosing needle is blocked, dosing needle is bent

Solution: Clean and replace the dosing needle

(3). Potential cause: Medium has hardened / cured

Solution: Clean the dispenser

(4). Potential cause: The dosing needle is too small or too long

Solution: Use a different dosing needle cross-section Reduce Dosing speed / flow rate

(5). Potential cause: Insufficient supply of medium

Solution: Increase the supply pressure. Check for air-bubbles. Check the hose line.

(6). Potential cause: Stator is swollen

Solution: Check material resistance, contact manufacturer

Why is it leaking or spilling after delivery ?

(1). Potential cause: Reverse flow not properly adjusted

Solution: Adjusting the reverse flow (instructions in the Operation manual)

(2). Potential cause: Bubbles in Medium

Solution: Ventilation medium

(3). Potential cause: Medium is compressible

Solution: Medium degassing.

Our services :

(1). Our screw pump series products have reasonable price, quality service, professional inspection. Welcome to customize.

(2). we have a special quality Supervision Department to ensure the quality of mass production.

(3). If the product has quality problems, we will deal with it at he first time, find out the cause and take responsibility.

(4). If you are interested in our products and companies, please leave a message or email us , we will give you an answer within 24 hours

Why choose us ?

(1). Factory Direct Sales, no intermediate links, competitive price

(2). Our machines are imported from Europe, the original machine factory, the production of stable product quality, do not use low quality equipment.

(3). Ensure on-time delivery, we can provide the best quality of service control, transportation, documentation and so on.

(4). We provide samples and OEM services.

(5). We will reply to your enquiry within 24 hours.

(6). More than 20 years of experience in this industry business, and professional team, so that our customers feel relaxed and comfortable working with us in

(7). Please contact us by email and we will send you more information.

How to make an order for Standard pump ?

(1). Sample approval

(2). Client arrange 30-50% deposit after receiving our PI (pro forma invoice)

(3). We start bulk production and finish production within agreed lead time

(4). We send product photo and shipping documents to client

(5). Client arrange balance payment

(6). We arrange the delivery, and send original documents or telex release the goods